продукц

- ▶ Titanium product center

- ■ Titanium plate

- ■ Titanium tube

- ■ Titanium rod

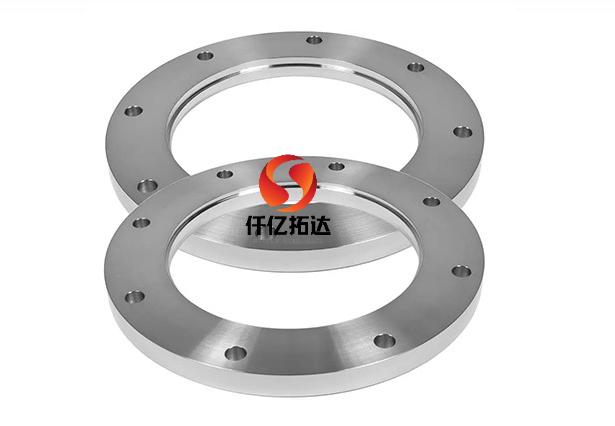

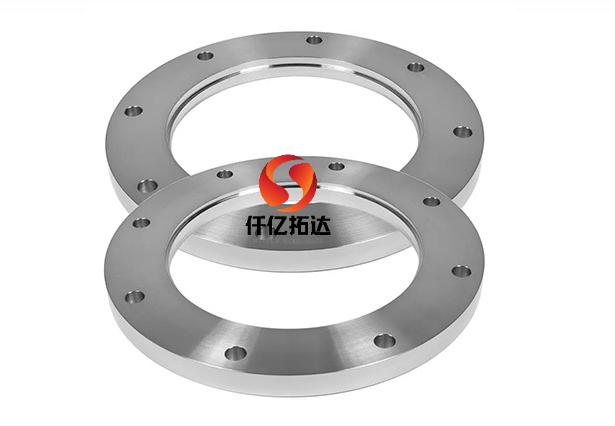

- ■ Titanium forgings. Flange

- ■ Titanium alloy

- ■ Titanium, nickel, zirconium material

- ■ Titanium standard

- ■ Titanium workpiece

- ■ Titanium, nickel equipment

- ▶ Nickel product center

- ■ Nickel-based alloy

- ■ Nickel tube

- ■ Nickel plate

- ■ Nickel rod

- ▶ Titanium agitator

- ■ Titanium reactor agitator

- ■ Titanium stirring blade

- ▶ Industrial instruments/sensors

- ■ Industrial instrument

- ■ Industrial sensor

- ■ Pressure instrument

- ■ Non-standard sensor

产品介绍

The applications of large-diameter titanium flanges are diverse, finding widespread use across various industrial sectors, including but not limited to:

-

Chemical Industry: Large-diameter titanium flanges are commonly employed to connect various vessels, reactors, and pipelines in chemical equipment, addressing the challenges posed by highly corrosive media and high-temperature environments.

-

Marine Engineering: Due to titanium's excellent corrosion resistance, large-diameter titanium flanges are often used in marine engineering, including applications in seawater desalination equipment and marine water treatment systems, ensuring stable operation in seawater environments.

-

Energy Sector: In the energy industry, these flanges are utilized to connect and support petroleum and natural gas pipelines, demonstrating corrosion resistance suitable for challenging oil and gas environments.

-

Aerospace: Large-diameter titanium flanges are employed in the aerospace sector for connecting critical components such as aircraft fuel systems and hydraulic systems, leveraging titanium's advantages of lightweight and high strength.

-

Fertilizer Production: Widely used in the fertilizer industry, these flanges connect reactors and separators, handling corrosive gases and liquids generated during chemical reactions.

The production process of large-diameter titanium flanges is a complex engineering endeavor involving several key steps to ensure the quality and performance of the final product:

-

Material Selection: Choose suitable industrial pure titanium or titanium alloy materials based on specific application requirements, determining the grade and specifications.

-

Cutting and Preforming: Employ cutting equipment to shape raw materials into appropriate forms and use preforming processes to achieve initial shaping.

-

Heating and Forming: Heat the preformed titanium material to the required temperature and use large molds or hydraulic forming equipment to shape it into the desired large-diameter flange.

-

Heat Treatment: Subject the formed large-diameter titanium flange to heat treatment to enhance its mechanical properties and corrosion resistance.

-

Machining: Precisely machine the heat-treated flange, including hole machining, thread machining, etc., ensuring dimensional accuracy and shape precision.

-

Welding: Weld the components of the flange that require assembly, ensuring high-quality welds and strong connections.

-

Surface Treatment: Perform surface treatments such as polishing and sandblasting to enhance the appearance and corrosion resistance of the large-diameter titanium flange.

-

Quality Inspection: Conduct thorough quality inspections, including dimensional checks, weld inspections, chemical composition analysis, etc., to ensure the product meets design requirements.

-

Packaging and Delivery: Carefully package the final large-diameter titanium flange using appropriate methods for timely delivery to customers.

Through this comprehensive production process, large-diameter titanium flanges are finely manufactured to meet the diverse requirements of engineering and industrial applications.