About Us

- Company Profile

- Corporate Culture

- Introduction to Titanium Alloy

- Introduction to Titanium Tube

- Introduction to Titanium Rod

- Introduction to Titanium Plate

- Introduction to Nickel Tube

- Introduction to Nickel Plate

- Introduction to Nickel Alloy

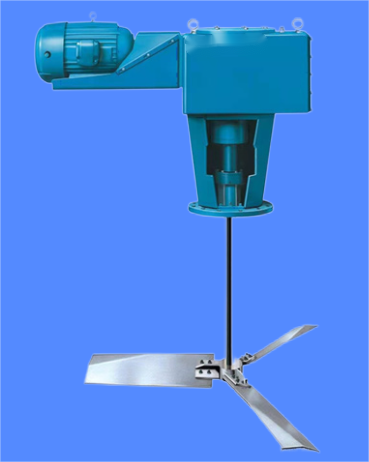

- Introduction to Titanium Stirrer

- Application of titanium agitator

- Industrial mixer

- Introduction to pressure instruments

- Introduction to Sensors

Forms of Industrial Stirrers:

-

Frame Agitator: Utilizes a frame structure, typically employed in large reactors or tanks for stirring, suitable for high-capacity mixing processes.

-

Spiral Agitator: Designed in a spiral form, often used for mixing viscous materials, such as high-viscosity liquids in chemical processes.

-

Paddle or Blade Agitator: Common form of agitation, applicable for general mixing processes, suitable for both liquid and gas-liquid mixing.

-

High Shear Agitator: Equipped with high-speed shear blades, suitable for processes requiring strong cutting and dispersion forces, such as food processing or particle dispersion.

-

Turbine Agitator: Comprised of turbine-shaped agitators, suitable for applications requiring high shear and mixing intensity, like dissolution reactions in the chemical industry.

-

Magnetic Stirrer: Driven by a magnetic field, often used in reactors where non-contact transmission or contamination-free conditions are essential.

Applications of Industrial Stirrers:

-

Mixing and Stirring: Ensures uniform blending of multiple raw materials, ensuring consistency in chemical reactions or physical processes.

-

Dissolution: Completely dissolves solid or liquid substances in a solvent, commonly seen in pharmaceutical and chemical production.

-

Gas-Liquid Mixing: Introduces gas into a liquid, for instance, in agitating air flotation devices used in water treatment.

-

High Shear Mixing: Used for dispersion, suspension, and homogenization of particles, prevalent in the food, cosmetic, and pharmaceutical industries.

-

Fermentation: Promotes the growth of microorganisms and fermentation processes, particularly in food and bioengineering.

-

Reactor Stirring: Employed for stirring chemical reactions in reactors, ensuring thorough mixing of reactants.

Processing Challenges:

-

Handling High Viscosity Materials: For highly viscous materials, stirrers need to provide sufficient power while preventing equipment blockage.

-

- Company Profile

- Corporate Culture

- Introduction to Titanium Alloy

- Introduction to Titanium Tube

- Introduction to Titanium Rod

- Introduction to Titanium Plate

- Introduction to Nickel Tube

- Introduction to Nickel Plate

- Introduction to Nickel Alloy

- Introduction to Titanium Stirrer

- Application of titanium agitator

- Industrial mixer

- Introduction to pressure instruments

- Introduction to Sensors

About Us

- Titanium plate

- Titanium tube

- Titanium rod

- Titanium forgings. Flange

- Titanium alloy

- Titanium, nickel, zirconium material

- Titanium standard

- Titanium workpiece

- Titanium, nickel equipment

- Nickel-based alloy

- Nickel tube

- Nickel plate

- Nickel rod

- Titanium reactor agitator

- Titanium stirring blade

- Industrial instrument

- Industrial sensor

- Pressure instrument

- Non-standard sensor

Product

- Company dynamics

- Product Q&A

- Titanium market

- Nickel metal industry

- Baoji sensor

- Mixer knowledge

News

- Shaanxi Qianyi Tuoda Technology Co., Ltd.

- Address: 4th Floor, Building 4, No.188 Gaoxin Avenue, Baoji City, Shaanxi Province

- Tel: +86-917-3557966(Company Office)

- Mobile: +86-15909236031 +86-15336169260(General Manager)

- Business first titanium :+86-15909236031; +86-18829679311

- Business second nickel :+86-15771678802

- Service three agitators :+86-15769278801; +86-13379488133

- Service four instruments - sensor :+86-18991723992

- Email: ceo@sxqytd.com(General Manager);

- Email :qy006@sxqytd.com(Assistant to the General Manager)

- Email :qy001@sxqytd.com(Manager of Business Department)

- Email :qy002@sxqytd.com(Manager of Department 2)

- Email :qy003@sxqytd.com(Manager of Department 3)

- The website is www.sxqytd.com

Contact Us