About Us

- Company Profile

- Corporate Culture

- Introduction to Titanium Alloy

- Introduction to Titanium Tube

- Introduction to Titanium Rod

- Introduction to Titanium Plate

- Introduction to Nickel Tube

- Introduction to Nickel Plate

- Introduction to Nickel Alloy

- Introduction to Titanium Stirrer

- Application of titanium agitator

- Industrial mixer

- Introduction to pressure instruments

- Introduction to Sensors

Shaanxi Qianyi Tuoda Technology Co., Ltd.

Introduction to Titanium Alloy

1. Production process of titanium alloy

First of all, let's have an in-depth understanding of the production process of titanium tubes. Titanium tube manufacturing is a complex and precise process, including raw material extraction, refining, melting, forging, rolling and final heat treatment and other steps. In this process, it is important to ensure the purity of the material and the stability of the crystal structure to ensure the excellent performance of the final product.

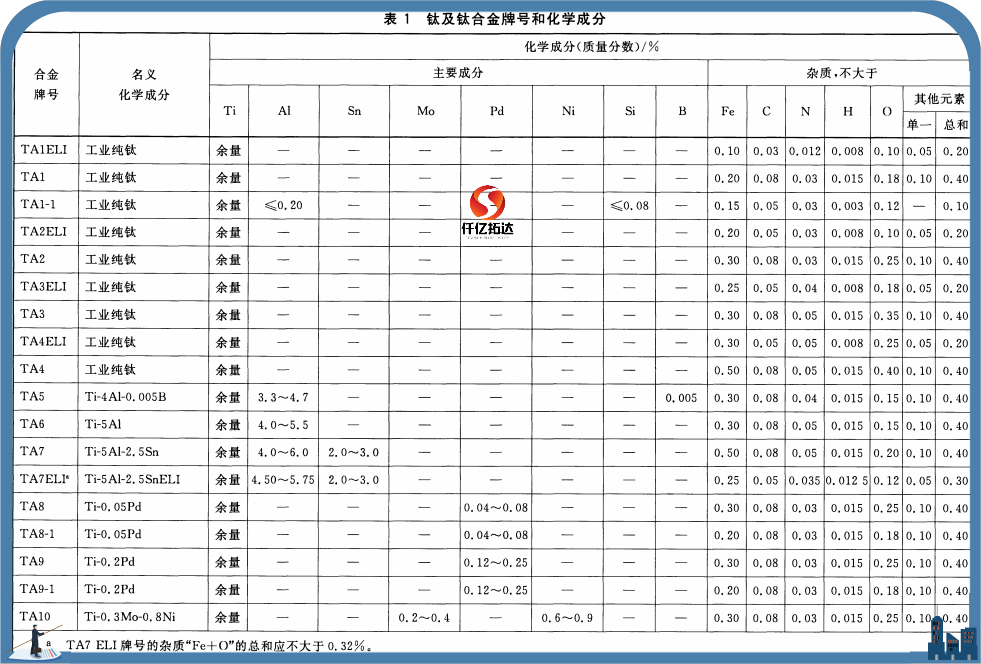

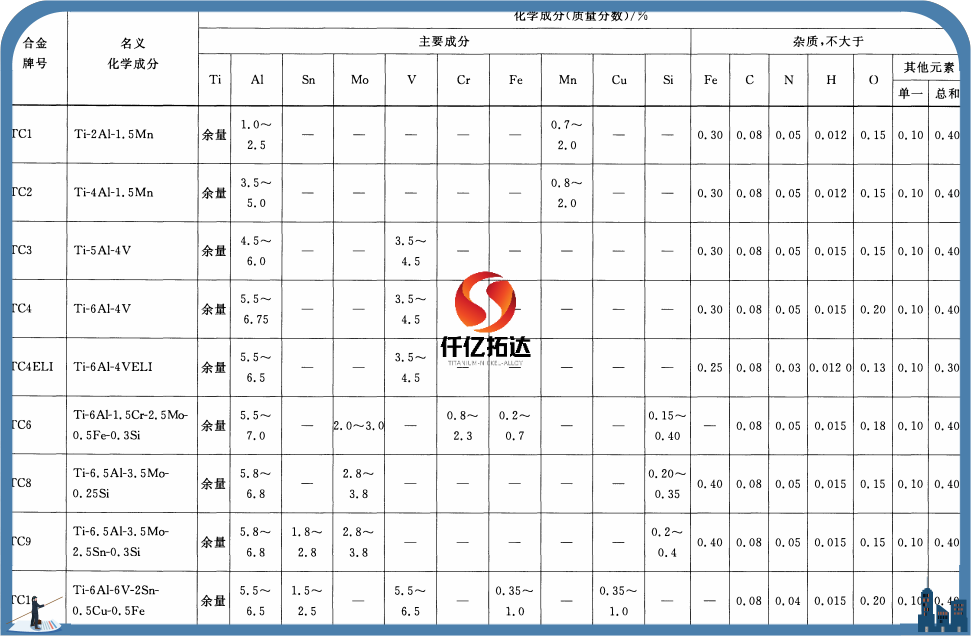

2. Specifications of titanium alloy

Titanium alloys are favored for their excellent strength, corrosion resistance and low density. Different specifications of titanium alloys have subtle differences in composition and heat treatment, and the formulation of these specifications strictly follows international standards to ensure that products meet the needs of various industries.

3. Titanium alloy is different from other alloys

Compared with traditional alloys, titanium alloys have unique advantages in terms of strength, corrosion resistance and weight. Compared with stainless steel, aluminum alloy, etc., titanium alloy is more suitable for some areas with high strength requirements and weight restrictions.

4. Use of titanium alloy

Titanium alloys are widely used in aerospace, medical equipment, chemicals, automobiles and sports equipment. Its excellent corrosion resistance and strength make it ideal for special environments, such as deep ocean development and aerospace engine parts.

5. Titanium alloy market demand

With the continuous development of high-tech industry, the demand for lightweight, high-strength, corrosion-resistant materials is increasing, so the titanium alloy market is showing a strong growth momentum. Especially in the aviation, medical and energy industries, the demand for titanium alloys is increasingly strong.

6. Varieties of titanium alloy

Different types of titanium alloys have their own unique performance characteristics, such as TA10, TA9, TC4 and TC2. These varieties have differences in strength, corrosion resistance and processing properties, so it is necessary to make reasonable choices according to the specific application scenarios when selecting materials.

7. Inspection in the production process of titanium alloy

In order to ensure the quality of titanium alloy products, the inspection in the production process is very important. Through the use of advanced testing equipment and technology, we are able to accurately determine the chemical composition, crystal structure and mechanical properties of materials to ensure the reliability of products.

8. Welding of titanium alloy

The welding of titanium alloys is a technically complex process that requires a high level of operating skills and precision equipment. In the welding process, it is necessary to pay attention to prevent oxidation, control temperature, and adopt appropriate welding methods to ensure the strength and corrosion resistance of welded joints.

9. Surface color of titanium alloy

The surface color of titanium alloy is diverse, which is not only the characteristics of the metal itself, but also related to the formation of the surface oxide layer. By adjusting the thickness and structure of the oxide layer, the metallic luster, golden yellow, blue purple and other color effects on the surface of the titanium alloy can be achieved.

10. Mechanical properties and chemical composition of TA10, TA9, TC4, TC2 titanium tubes

TA10: Excellent strength and corrosion resistance for high temperature environments. Mechanical properties are strengthened, chemical composition is stable.

TA9: With high tensile strength and plasticity, it is widely used in aerospace fields. Its chemical composition ensures excellent performance.

TC4: A typical representative of titanium alloys, with excellent strength, corrosion resistance and welding properties. Widely used in aviation, medical and other fields.

TC2: With balanced mechanical properties and excellent corrosion resistance, it is an ideal structural material for a variety of engineering applications.

Titanium alloy introduction

Titanium alloy TC4 material:

Production process:

The detailed preparation process of TC4 titanium alloys ensures that each alloy has excellent strength and corrosion resistance, providing solid support for your engineering.

Specifications:

Customized TC4 titanium alloys help you achieve greater results in high temperature and high strength environments.

Different from other materials:

TC4 titanium alloy has higher strength and high temperature resistance than pure titanium, and is your best partner in extreme conditions.

Purpose:

TC4 titanium alloy is widely used in aviation, aerospace and other fields to provide excellent performance guarantee for your project.

Market demand:

With the vigorous development of high-tech industry, the demand for TC4 titanium alloy continues to rise, becoming a highly sought after high-performance material in the market.

Breed:

A wide variety of options, from sheet to bar, to meet the diverse needs of different projects.

Inspection during production:

Strict quality control and advanced testing means ensure that every TC4 titanium alloy is in line with excellence