-

Specifications and dimensions of nickel tubes? 2024/03/11

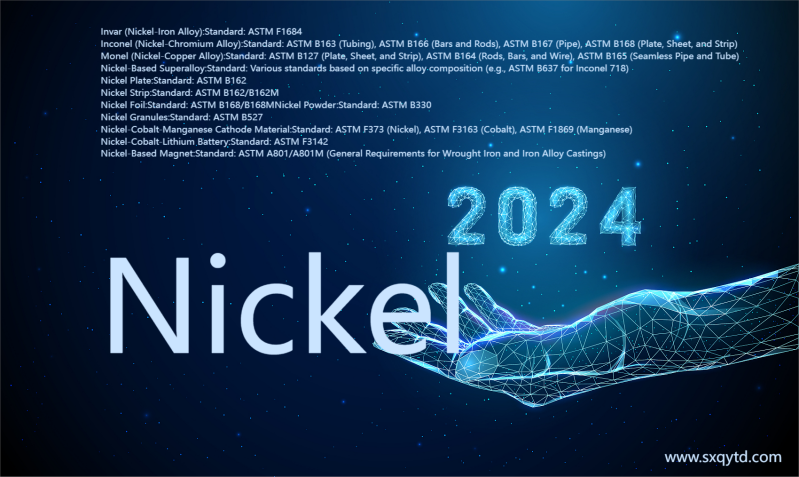

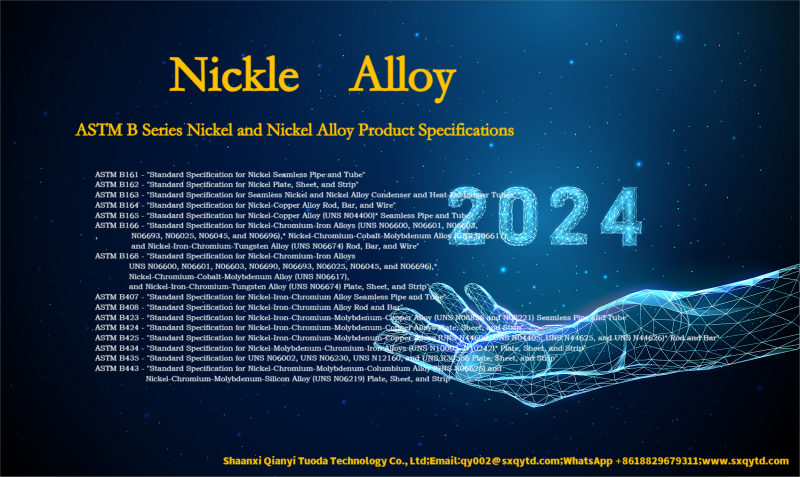

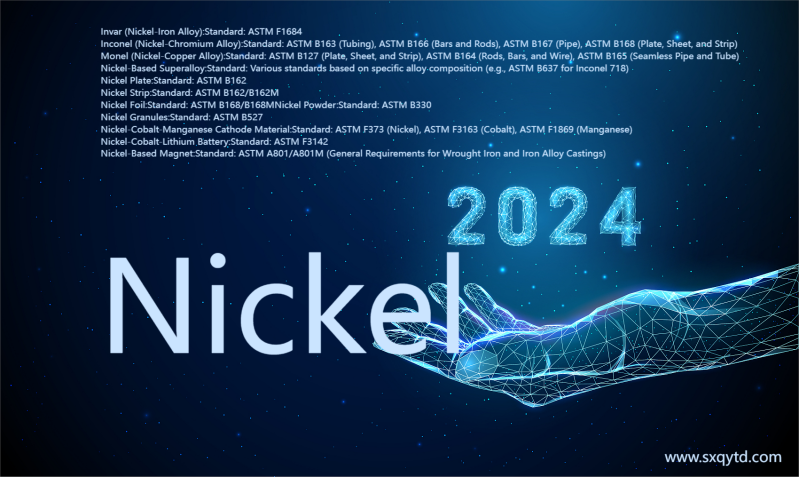

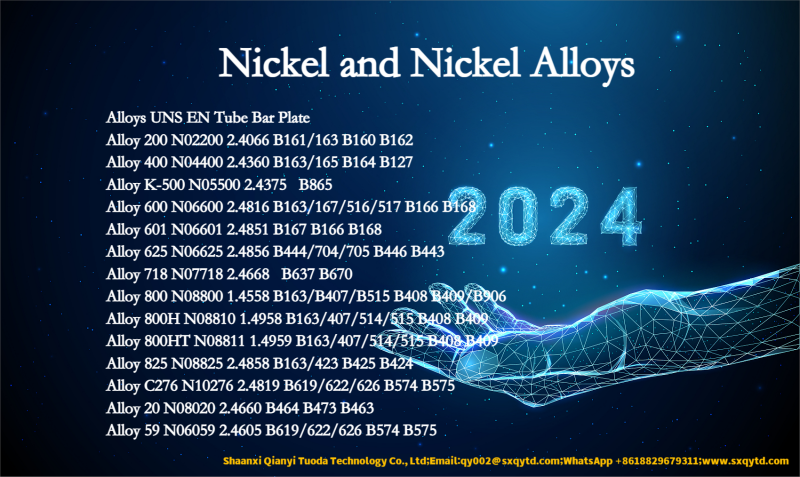

Specifications and dimensions of nickel tubes? The essence of nickel tubes lies in their composition, dimensions, and applications: Material Quality: Nickel tubes are crafted from high-quality nickel alloys like Nickel 200, Nickel 201, Inconel, Monel, or Hastelloy. These alloys offer exceptional resistance to corrosion, hig...

-

HASTELLOY C-276 (UNS N10276)--CHINA 2024/03/07

HASTELLOY C-276 (UNS N10276) Offers resistance to reducing and mildly oxidizing environments, and is resistant to localized attack and to stress-corrosion cracking . Used widely in the chemical and process industries and for aggressive environments in the pollution control industry. Chemical composition Ni: 57.0 min ...

-

INCOLOY 825 (UNS N08825)--china 2024/03/07

INCOLOY 825 (UNS N08825) A Ni-Fe-Cr-Mo Ti-stabilized alloy with excelle nt resistance to sulfuric and phosphoric acids. Resistant to reducing and oxidizi ng acids, pitting, stress-corrosion cracking and intergranular corrosion, it is used in chemical and petrochemical processing , oil and gas extraction, pollution control, was...

-

INCOLOY 800HT (UNS N08811)--BAOJI 2024/03/07

INCOLOY 800HT (UNS N08811) An alloy with strength and corrosion-resistance for use in chemical, petrochemical and food processing, for nuclear engineering and for the sheathing of electrical heating elements For use generally at temperatures below 1200 °F (650°C) Chemical composition Ni:30.0-35.0 Ti: 0.25-0.60 Fe:39.5 min ...

-

INCOLOY 800H (UNS N08810) 2024/03/07

INCOLOY 800H (UNS N08810) An alloy with strength and corrosion-resistance for use in chemical, petrochemical and food processing, for nuclear engineering and for the sheathing of electrical heating elements. For use, generally, at temperatures below 1200°F (650°C). Chemical composition Ni: 30.0-35.0 Ti: 0.15-0.60 Fe: 39.5 ...

-

ALLOY BAOJI--INCOLOY 800 (UNS N08800) 2024/03/07

INCOLOY 800 (UNS N08800) An alloy with strength and corrosion-resistance for use in chem ical, petrochemical and food proc essing, for nuclear engineering and for the sheathing of electrical heating elements. For use, generally, at temperatures below 1200°F (650°C). Chemical composition Ni : 30.0-35.0 S: 2 ...

-

INCONEL 690 (UNS N06690)--BAOJI 2024/03/07

INCONEL 690 (UNS N06690) An alloy with excellent high temperature corrosion - resistance for applications including nuclear steam generators, petrochemical processing, coal gasification, and sulfuric, nitric and nitric/hydrofluoric acid processing. Chemical composition Ni: 58.0 min S: 0.015 max Cr: 27.0-31.0 Si: 0.5 max F...

-

BAOJI-MONEL K-500 (UNS N05500) 2024/03/07

MONEL K-500 (UNS N05500) Similar to MONEL alloy 400 but age-harden able for higher strength and hardness. Used for pump shafts, oil well tools, doctor blades, springs, fasteners and marine propeller shafts. Chemical composition Ni: 63.0 min C: 0.25 max Cu: 27.0-33.0 Mn: 1.5 max Al: 2.30-3.15 S: 0.01 max Ti: 0 .35...

-

MONEL 400 (UNS N04400)--BAOJI NICKLE 2024/03/07

MONEL 400 (UNS N04400) A Ni-Cu alloy with high strength and excellent resistance to a range of media including seawater, dilute hydrofluoric and sulfuric acids, and alkalies. Used in marine and offshore engineering, salt production, feed water heaters, and chemical and hydrocarbon processing. Chemical composition Ni: 63.0...

-

NICKEL 201 (UNS N02201) 2024/03/07

NICKEL 201 (UNS N02201) Similar to Nickel 200 but with low carbon controlled to prevent inter granular embrittlement at above 600°F (315°C). Used for ch emical and process plants. Chemical composition Ni: 99.0 min Si: 0.02 max Cu: 0.25 max S: 0.01 max Fe: 0.40 max Mn: 0.35 max C: 0.15 max Specif...

-

NICKEL 200 (UNS N02200)--BAOJI 2024/03/07

Corrosion-Resistant Alloy Metal materials in the corrosive medium has the ability of resistance to medium erosion, corrosion resistance. Alloying method is adopted for corrosion resistant alloy: improving the thermodynamic stability of the metal or alloy; Joining is easy passivation alloy elements; Join the prompt productio...

-

NIMONIC 90 (UNS N07090)--BAOJI ALLOY METAL 2024/03/07

NIMONIC 90 (UNS N07090) An age harden able super-alloy for service at up to 1700°F (925°C). used for turbine blades, discs, forgings, ring sections, hot-working tools. Chemical composition Ni: Remainder C: 0.13 max Zr: 0.15 max Cr: 18-21 Mn: 1.0 max Pb: 0.002 max Co: 15-21 Si: 1.0 max B: 0.02 max Al: 1.0-2.0 ...

-

NIMONIC 80A (UNS N07080) 2024/03/07

NIMONIC 80A (UNS N07080) An age hard-enable creep resistant t alloy for service at temperatures up to 1500°F (815°C). Used for gas turbine components (blades, rings and discs), bolts, nuclear boiler tube supports, die casting inserts and cores, and for automobile exhaust valves. Chemical composition Ni: Remainder Si: 1 .0 ...

-

NIMONIC 75 (UNS N06075) 2024/03/07

NIMONIC 75 (UNS N06075) Ni-Cr alloy with good high temperature strength and outstanding oxidation resistance. Used in engine applications. Chemical composition Ni: Remainder Si: 1 .0 max Cr: 18-21 Ti: 0.2-0.6 Cu: 0.5 max C: 0.08-0.15 Fe: 5.0 max Mn: 1.0 max Specification Bar, Rod, Wire: BS HR 5 BS HR 504 DIN 17752...

-

INCOLOY A-286 (UNS S66286)-BAOJI NICKLE ALLOY 2024/03/07

INCOLOY A-286 (UNS S66286) An age hardenable Fe-Ni-Cr alloy with good strength and oxidation resistance up to 1300°F (700°C). Chemical composition Ni: 24.0-27.0 V: 0.1-0.5 S: 0.03 max Cr: 13.5-16.0 C: 0.08 max B: 0.001-0.01 Fe: Remainder Mn: 2.0 max Ti: 1.90-2.35 Si: 1.0 max Mo: 1.0-1.5 Al: 0.35 max S...

-

INCONEL X-750 (UNS N07750)--BAOJI 2024/03/07

INCONEL X-750 (UNS N07750) An age hardenable Ni-Cr alloy with high tensile and creep rupture properties up to 1300°F (700°C). Chemical composition Ni: 70.0 min Nb: 0.7-1.2 Cu: 0.5 max Cr: 14.0-17.0 C: 0.08 max Co: 1.0 max Fe: 5 .0-9.0 Mn: 1 .0 max Ti: 2.25-2.75 Si: 0.5 max ...

-

BAOJI-INCONEL 718 (UNS N07718) 2024/03/07

INCONEL 718 (UNS N07718) An age harden able Ni-Fe-Cr alloy, certainly among the most versatile, combining high strength at up to 1300°F (700°C) with corrosion resistance and excellent Weld ability. Chemical composition Ni: 50.0-55.0 Ti: 0.65-1.15 Si: 0.35 max Cr: 17.0-21.0 Al: 0.2-0.8 P: 0.015 max Fe: Remainder Co: 1.0 m...

-

CHINA-BAOJI-INCONEL 625 (UNS N06625) 2024/03/07

INCONEL 625 (UNS N06625) A Ni-Cr-Mo alloy with good strength at up to 1500°F (815°C) and excellent resistance to a wide variety of corrosive media. Chemical composition Ni: 58.0 min C: 0.1 max Ti: 0.4 max Cr: 20.0-23.0 Mn: 0.5 max P: 0.015 max Mo: 8 .0 - 10.0 Si: 0 .5 max Co: 1 .0 max Nb: 3.15-4.15 S: 0.015 max Fe: 5.0 ...